CNC Turning

| MACHINE MAKE | MACHINE | WORKING RANGE | YOM |

| ACE | SJE10 | Dia 200X525mm | 2022 |

| ACE | SJE10 | Dia 200X525mm | 2022 |

| LMW | LL20T-L7 | Dia 250X650mm | 2020 |

| ACE | JOBBER | Dia 200X300mm | 2015 |

| JYOTI | DX200-5B | Dia 250X425mm | 2011 |

| PACEMAKER | Mini150 | Dia 150 X 600mm | 2019 |

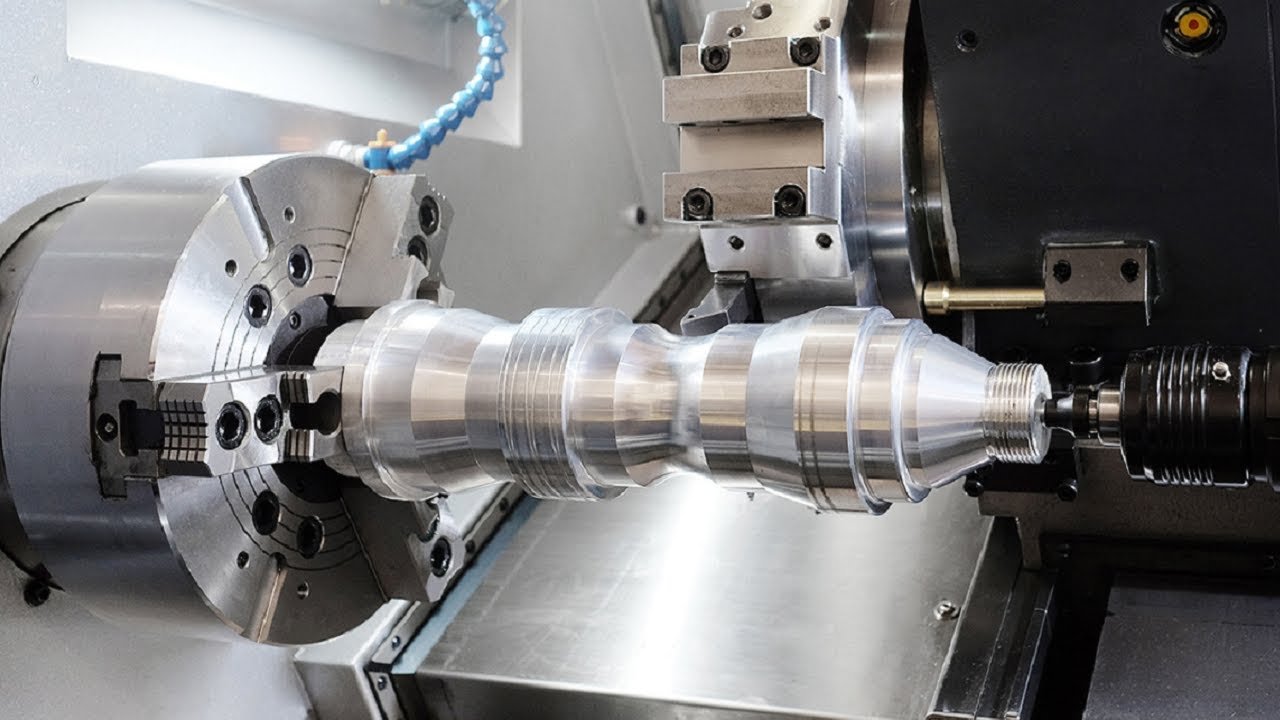

For CNC turning, we work with an impressive list of companies. Our excellent reputation for speed and efficiency places us firmly at the forefront of the industry. From simple to highly complex external geometries and internal bores, our precision turning capability will meet the highest specifications with accuracy, repeatability and speed. With our carefully selected partners, we have the choice of a vast array of high-speed CNC turning lathes, we will know the perfect choice to meet your exact requirements quickly and cost-effectively.

CNC turning machines are a cornerstone in CNC machining manufacturing, offering precision and efficiency in producing high-quality CNC machined components. These machines utilize computer numerical control (CNC) to automate the rotation of workpieces, enabling precise cutting, drilling, and shaping. The process begins with a solid block of material meticulously turned and sculpted by the CNC machine services to achieve the desired specifications.

- Fast and efficient service

- Advanced manufacturing capabilities

- Precision turning of ferrous and nonferrous metals

- Quantities from 1 to 1000 numbers.

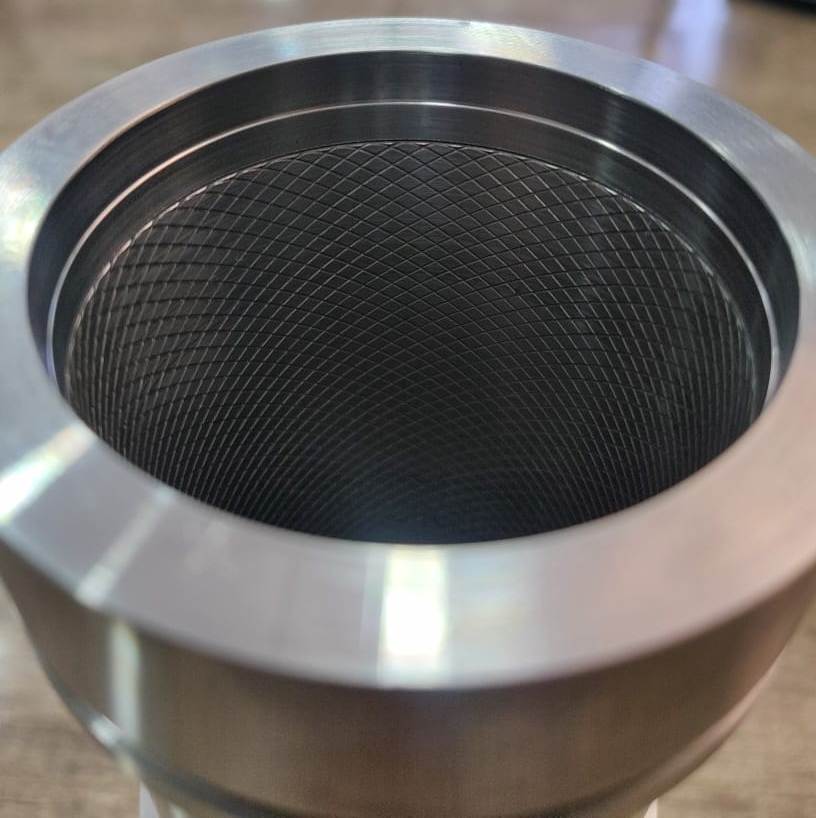

Diamond Machine Parts

CNC TurningCoupling

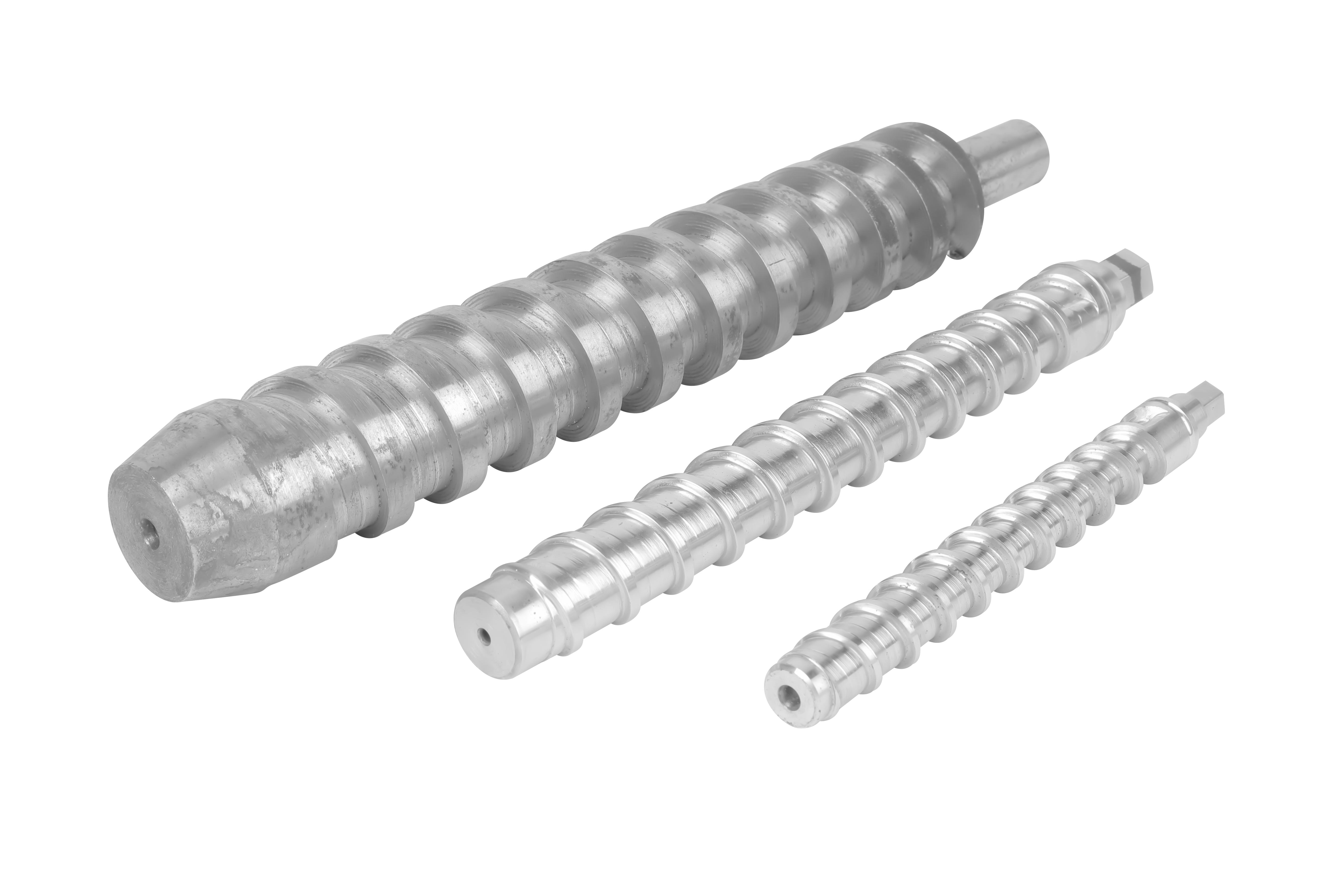

CNC TurningScrew Turning

CNC TurningCustomised Parts

CNC TurningValve Machining

CNC TurningCNC Shaft Machine

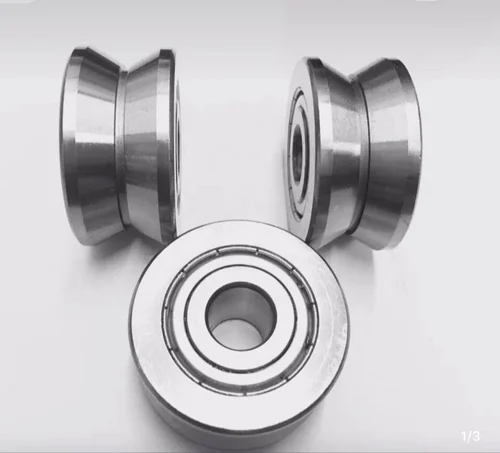

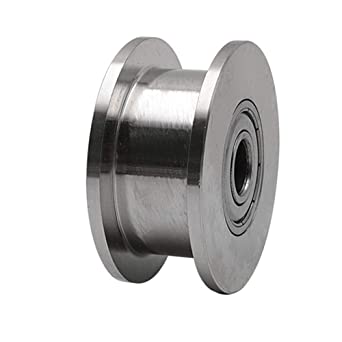

CNC TurningProfile Roller

CNC TurningPlastic Molding Dies

CNC Turning

Following are the advantages of CNC turning:

- Increasement in productivity

- Higher accuracy

- Low rate of wastage of material

- Less time consuming

- Safe working process

- No requirement for a highly skilled operator

- Good quality and affordable machinery

- Less workforce require

The following are the CNC turning machine parts:

- Chuck

- Headstock

- Tailstock

- Turret

- Footswitch

- Foot pedals

- Cutting tool

- CNC control panel

CNC turned components are three in general:

CNC is a program consisting of various instructions, machine control units, and processing equipment, also called machine tools.

CNC turning machine price is affordable to those wanting to purchase this as it is a high-tech machine with the best quality parts and gives the best possible results. Keytex machines provide the best CNC turning machine parts in India.