Diamond Machines

Diamond machine manufacturing involves the development of machinery and equipment used in various diamond production processes. These machines are designed to cut, grow, polish, and improve the quality of natural lab-grown diamonds. Let’s examine the basic steps involved in the manufacture of diamond tools.

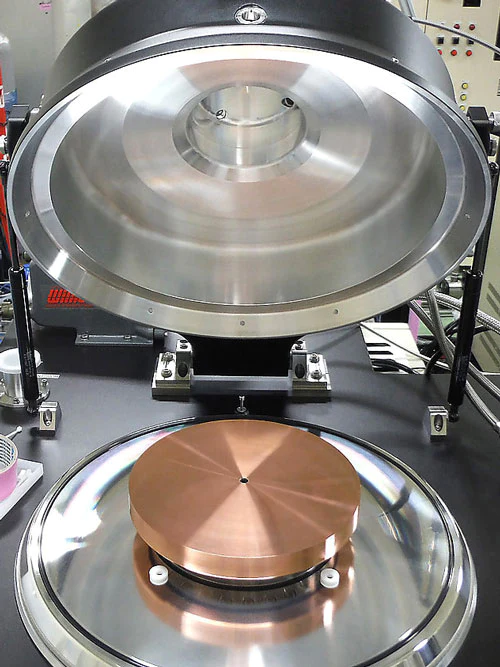

Laboratory-grown diamonds, also known as synthetic or cultured diamonds, can be produced using a variety of methods. One of the most common methods is chemical vapor deposition (CVD). For laboratory-grown diamonds, the CVD process uses specialized equipment.

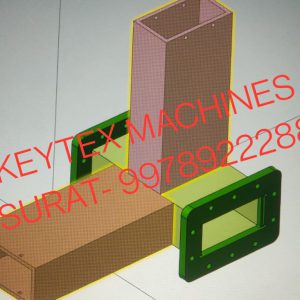

Diamond machines are essential tools in the gem industry, ensuring accuracy and efficiency. A diamond-cutting machine ensures a flawless cut, giving the stone greater luster. The machinery used in the laboratory processing of diamonds is critical to producing high-quality diamond machines, accurately replicating the natural conditions. These high-quality making diamond machines are essential for producing high-quality diamonds Machine for a variety of applications, from jewelry to industrial applications.

Diamond Machine

Diamond Machines

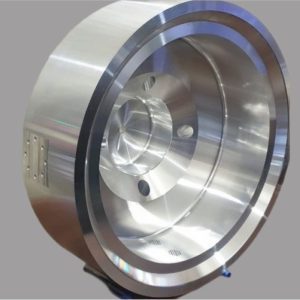

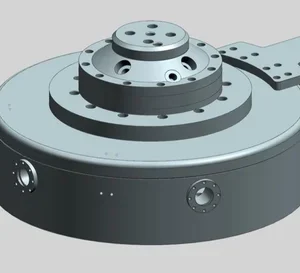

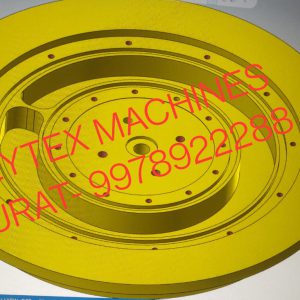

A diamond cutting machine is specialized equipment used to cut and shape diamonds with precision. It uses laser technology or mechanical saws to ensure flawless cuts.

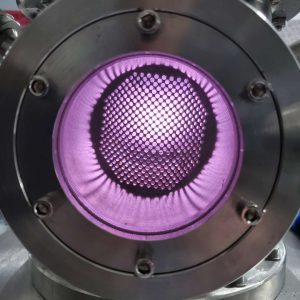

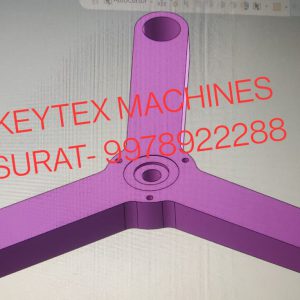

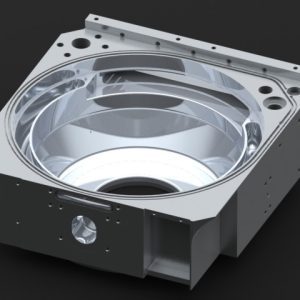

CVD (Chemical Vapor Deposition) machines use plasma-enhanced technology to grow synthetic diamonds under controlled conditions. These machines mimic the natural diamond formation process to produce high-purity lab-grown diamonds.

Yes, our machines are engineered to process both natural and lab-grown diamonds efficiently, ensuring superior quality and precision.

Diamond machines are widely used in jewelry manufacturing, industrial tooling, electronics, medical, aerospace, and automotive sectors for various applications.

Yes, we offer customized solutions based on specific industry needs. Our experts work closely with clients to develop machines that match their exact requirements.

Our machines offer micron-level precision, ensuring high-quality finishing and minimal material wastage.

Yes! We provide customized solutions tailored to your specific diamond processing requirements.

Regular maintenance includes cleaning, lubrication, and timely replacement of worn-out parts to ensure optimal performance.

Yes! We offer installation, training, and ongoing technical support to help you operate your machine efficiently.

You can contact us via:

📞 Phone: +91 9978922288

📧 Email: keytexmachines@gmail.com

🌐 Website: www.keytexmachines.com