At Keytex Machines, we specialize in high-precision VMC job work services, delivering exceptional accuracy and efficiency for machining complex components. With our advanced Vertical Machining Centers (VMCs) and cutting-edge CNC technology, we offer customized machining solutions that meet the highest industry standards.

Why Choose Our VMC Job Work Services?

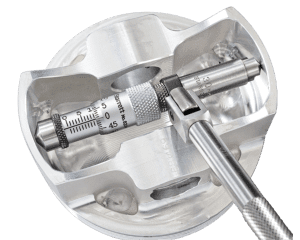

- Precision Engineering – Achieve tight tolerances with superior surface finishing.

- Versatile Material Expertise – Specializing in steel, aluminum, brass, and other alloys.

- Custom Machining Solutions – Tailored to specific client requirements across industries.

- Advanced CNC Technology – Ensuring consistent, high-speed, and efficient production.

- Multi-Industry Applications – Serving automotive, aerospace, medical, textile, and engineering sectors.

Our VMC Capabilities Include:

- Prototyping & Mass Production – From one-off parts to large-scale manufacturing.

- Complex Component Machining – Ideal for precision tools, dies, and intricate parts.

- Surface Finishing & Detailing – Ensuring smooth, flawless surfaces for optimal performance.

- Custom Fixture & Tooling – Designed to maximize efficiency and accuracy.

At Keytex Machines, we are committed to delivering superior quality and high-precision machining solutions that enhance performance, durability, and reliability.